Imbert Gasifier

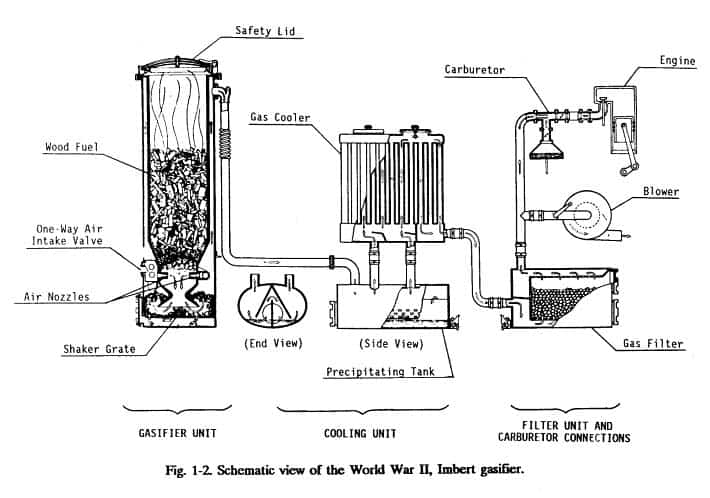

Imbert Gasifier. The constricted hearth, downdraft gasifier pictured below is called the Imbert gasifier, after the inventor Jacques Imbert. (more detail is in the FEMA plans). However, other names and brands manufactured the gasifier.

Many European auto companies, including General Motors; Ford; and Mercedes Benz, mass-produced these units during WWIIFord; and Mercedes Benz. Many homemade units also lasted about 20,000 miles, while factory-made systems operated for anything up to 100,000 miles.

In the plan below, the upper part of the cylinder is the hopper holding chips or other wood material. The hopper requires filling every couple of hours or as needed. The cover or ‘safety lid’ is heavily spring-loaded, allowing the lid to open and relieve pressure build-up should an explosion occur.

The lower part of the cylinder contains an airtight chamber with two openings on either side. One opening allows for air intake, while the other allows exhaust gas exit.

The fuel enters the bottom chamber through one of these openings, where it meets with hot exhaust gases. The upper section draws the volatile gases as combustion occurs. They mix with the incoming air to create combustible syngas, replacing gasoline or diesel fuel in engines.

The constant flow of air into the bottom chamber keeps temperatures within an optimal range. The increase in combustion efficiency results in fewer pollutants. Compared to traditional methods, such as burning wood directly with little airflow control. Filtering exhaust gases reduce particulate matter.

Note that the air nozzles at the unit’s base draw air into the fuel source for gasification. The Imbert requires low moisture (less than 20% moisture) and a uniform blocky fuel to allow gravity feeding through the constricted hearth.

Imbert Gasifier Disadvantages

Even as a prototype, the gasifier has several disadvantages. The hearth constriction seriously limits the range of fuel shapes that can be gasified successfully. The Imbert requires high-grade hardwood fuel at least 2cm long, with less than 20% moisture content. The design is not easily up-scaled as the air from the side cannot penetrate a large-diameter fuel bed. If the unit is to supply gas to internal combustion engines, the gas requires scrubbing to remove tars. Please take a look at the 2022 paper on design and experimental tests in the download section.